Forging and Stamping Custom Sheet Automotive Metal Stamping Product Precision Sheet Progressive Metal Stamping

forging and stamping Custom Sheet automotive Metal Stamping product Precision Sheet progressive Metal Stamping Products

Description

Basic Info

| Model NO. | GL0013 |

| Type | Cold Stamping |

| Processing Type | Shaping Metal |

| Material | Steel, Stainless Steel, Brass, Copper |

| Mould | Multistep Progressive Dies |

| Surface Processing | Powdercoated, Polishing, Electroplating, Anodizin |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | International Standard |

| Customized | Customized |

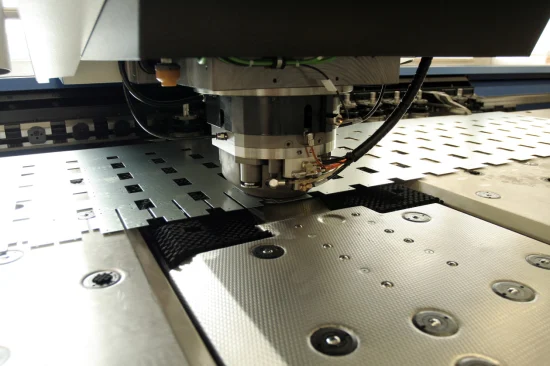

| Working Process | Laser Cutting Bending Stamping Welding |

| Quality | 100% Inspection Before Shipping |

| Leadtime | 2-4weeks |

| Shipping Way | by Sea;by Air;Door to Door |

| Transport Package | Plastic Bag + Shipping Carton |

| Specification | Customize |

| Trademark | Great Lion |

| Origin | Hebei, China |

| HS Code | 7326909000 |

| Production Capacity | 2000000PCS Per Month |

Product Description

forging and stamping Custom Sheet automotive Metal Stamping product Precision Sheet progressive Metal Stamping

Products Description

| Material | Stainelss steel 304 , 316 , 202 , 201 ,430 . Aluminum 6061 , 6062 ,5052 , Brass , Copper , Cold Rolled Steel , Hot Rolled Steel |

| Size Range | Min 3.0 X 3.0 mm , Max 1000 X 2000 mm |

| Dimensions | As client's requirement |

| Thickness | 0.4--20.0 mm |

| Surface Treatment | Powder coating ,Painting ,Shot blasting, Polsihing ,Electrical galvanizing, Chemical galvanizing, Chrome plating , Nickel Plating, Tumbling, Passivation etc. |

| Machining | Stamping machine for 6.3 Tons to 160 Tons . |

| Support Software | Pro-E , UGS , SolidWorks ,AutoCAD |

| Quality Control | Chemical analysis, mechanical properties, impact testing, pressure testing, 3-D co-ordinate CMC, metallography, magnetic particle flaw inspection, etc. |

| MOQ | 1000pcs |

| Package | Carton and Pallet , exact part with package every pc |

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)We have a professional engineer team to design custom parts for your remand, we also have a lot of ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

Production Process

| Q1.Will my design drawings be safe when you get it ? |

| Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings. |

| Q2.Is it possible to know how are my products going on without visiting your company? |

| We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |

| Q3.Can you send me samples ? |

| Yes, Samples are for free, and freight is on your side. |

| Q4.How long is the lifetime ? |

| Anodizing for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| Q5.What is the payment terms ? |

| T/T: 30% deposit, the balance will be paid before delivery;L/C: the balance irrevocable L/C at sight. |

Prev: Custom Metal Auto Parts Stainless Steel Sheet Carbon Steel Precision Stamping

Next: OEM Design Steel/Sheet Metal Fabrication Laser Cutting Welding Metal Parts Stamping Accessories

Our Contact

Send now