Customized Sheet Electrical Contact Shaping Metal Stamping Part Aluminum Stamping Metal Stamping for Forming Process with Multistep Progressive Dies

Description

Basic Info

| Model NO. | stamping |

| Processing Type | Shaping Metal |

| Material | Stainless Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customized | Customized |

| Surface Finished | Powder Coating, Electroplating, Oxidation and More |

| Material Type | Stainless Steel, Iron, Aluminum, Galvanized |

| OEM | Accept |

| Design | CAD, 3D |

| Sample | 25 Days |

| Payment Items | T/T, L/C |

| Ship Items | Fob, CIF, DDP, Fca and More |

| Lead Time | 15-20 Days |

| Packing | Carton Box, Pallet, Wooden Box |

| Shipping Way | Air, Sea |

| Produce Capacity | 2000-10000PCS/Day |

| Used | Auto Part/Furniture/Engineering/More |

| Transport Package | Carton Box and Wooden Box |

| Specification | stainless steel, carbon steel, aluminum and more |

| Trademark | TOP |

| Origin | Jiaxing City, Zhejiang Province |

| Production Capacity | 50000 PCS Per Month |

Product Description

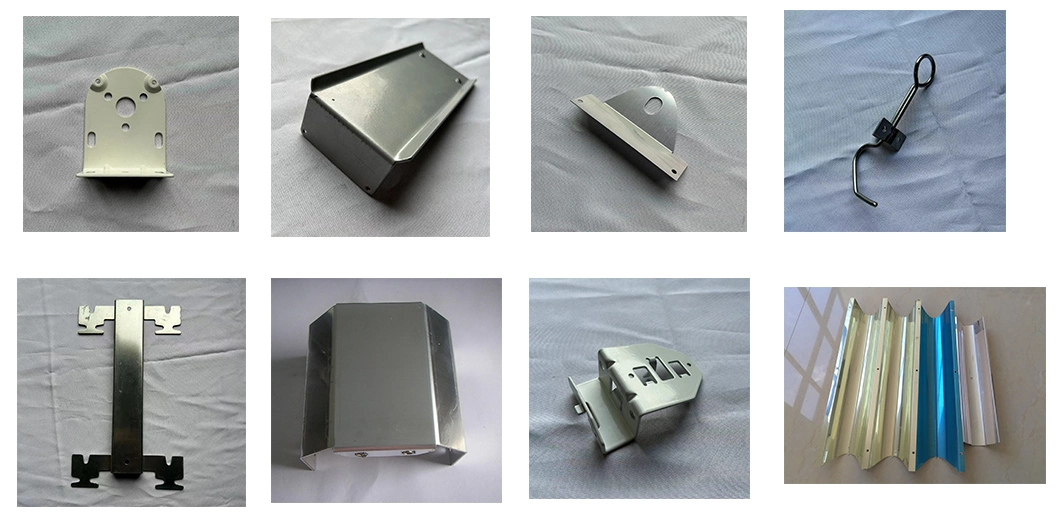

Why you chose Jiaxing Top Machinery? Quality is the soul of an enterprise.Our factory start working in manufacturer of metal stamping, pipe machined parts, drawing parts,auto stamping parts and other hardware products

The material we could use stainless steel,aluminum,carbon steel,copper and more.The surface finished we have electroplating,Spraying,polishing,Oxidation and more

We are professional to our job.What we can suit is most of our products are customized ones due to every client's needs. Pls feel free to tell me your required one, and I will not let you down.

OEM/ODM/Customized metal stamping products are welcomed !!

All the work can be done with us,let's start it now!!

Click here for your first talking!!

Product DescriptionStamping Products Our best businessCutting, bending, welding or others

Most of stamping parts have their own drawings or the samples. If you could show us your drawings or samples, we can do it as the same like them. Of course, if you want to do some changes, that is no problems.

Drawn Parts

Most of drawn parts have their own drawings or the samples. If you could show us your drawings or samples, we can do it as the same like them. Of course, if you want to do some changes, that is no problems.

If the hinges are not standard, you can not find in the market, call us, we can do them.Solar accessories - metal flashing roofSolar metal rain shield for various series of solar electricity.The pool board or bracket system fits all types of houses top, perfect waterproof and support integration effect.Solar accessories - Mounting bracket supportThe bracket system is used to install the solar metal flasing roof and support solar panel system, etc., perfect each match Links between pieces.

The heat treatment is necessary, it must do in our mold or our metal products.Customized metal stamping parts

| Product name | Customized metal stamping parts |

| Design | We use the most advanced products design as software Auto CAD,Pro/E,Solidworks,UG (DWG,DXF,IGS,STP,X-T) |

| Manufacture | We use the advanced technology,unmatched skills,professional and advanced equipment size range from 15T-315T,and experienced technicians to fit our customers' requirements,like tooling manufacturing,stamping,welding,cutting,bending,and surface finish service. |

| Product material | stainless steel,carbon steel,aluminum,aluminum alloy,spring steel,brass or others |

| Making process | Progression die, Stamping, deepdrawn, Bending, Punching, Cutting, Polishing, Threading, welding,Tapping,Riveting,Grinding,CNC machining. |

| Surface finish | Powder coating,electroplating,galvanized or more. |

| Price terms | FOB Shanghai/Ningbo,EXW factory price |

| Lead time | 20-45 days based on the different products and different quantities. |

| Packaging | Canton case or as per customers' requirement |

| Certification | ISO9001:2008 |

| Industry | These parts are used in Engineering construction, Automotive, Electrical, Building, Furniture, Machine assembly ,Computer, Air industry,OEM/ODM parts. |

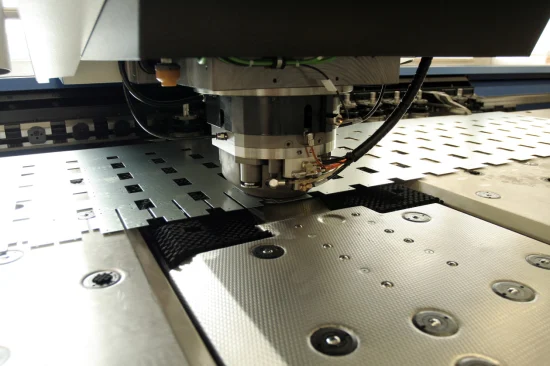

1.Stamping/Puching

2.Bending/Forming service

3.Welding service

4.Laser cutting service

5.CNC machine service

6.Structural steel service

7.Different material products8.Polishing service

9.Customized metal stamping design and produce service

This is the stamping production detailsThis is the surface finished work room

| Package shop |

This is the packing work shop,package types you can chose

| Material Shop |

This is the development room, our enginner is working here and all the molds is making here

| Office and sample room |

CertificationsShipping ways

Click here for your first talking!!

FQA :| Q1 | Are you a manufacturer or the trading company? |

| A1 | A company integrated with industry and trade. |

| Q2 | What about the shipping methods? |

| A2 | For urgent order and light weight,you can choose the following express:UPS,Fedex,TNT,DHL,EMS. For heavy weight,you can choose to deliver the goods by air or sea. |

| Q3 | what about the payment methods? |

| A3 | L/C,T/T,assurance trade. |

| Q4 | How much does it cost to ship to my country? |

| A4 | It depends on seasons,The charge is different in the different seasons. |

| Q5 | What's your delivery time? |

| A5 | Usually we produce within 25-30 days after the payment confirmed. |

| Q6 | Can i print our logo/barcode/unique QR code/serles number on products? |

| A6 | Yes,of course. |

| Q7 | Can i order some sample for our testing? |

| A7 | Normally,sample is free,but as for special samples,it needs some charge. |

| Q8 | Can u customize my products in special shape? |

| A8 | Yes,we can offer OEM and ODM |

Our Contact